ProteanDrive

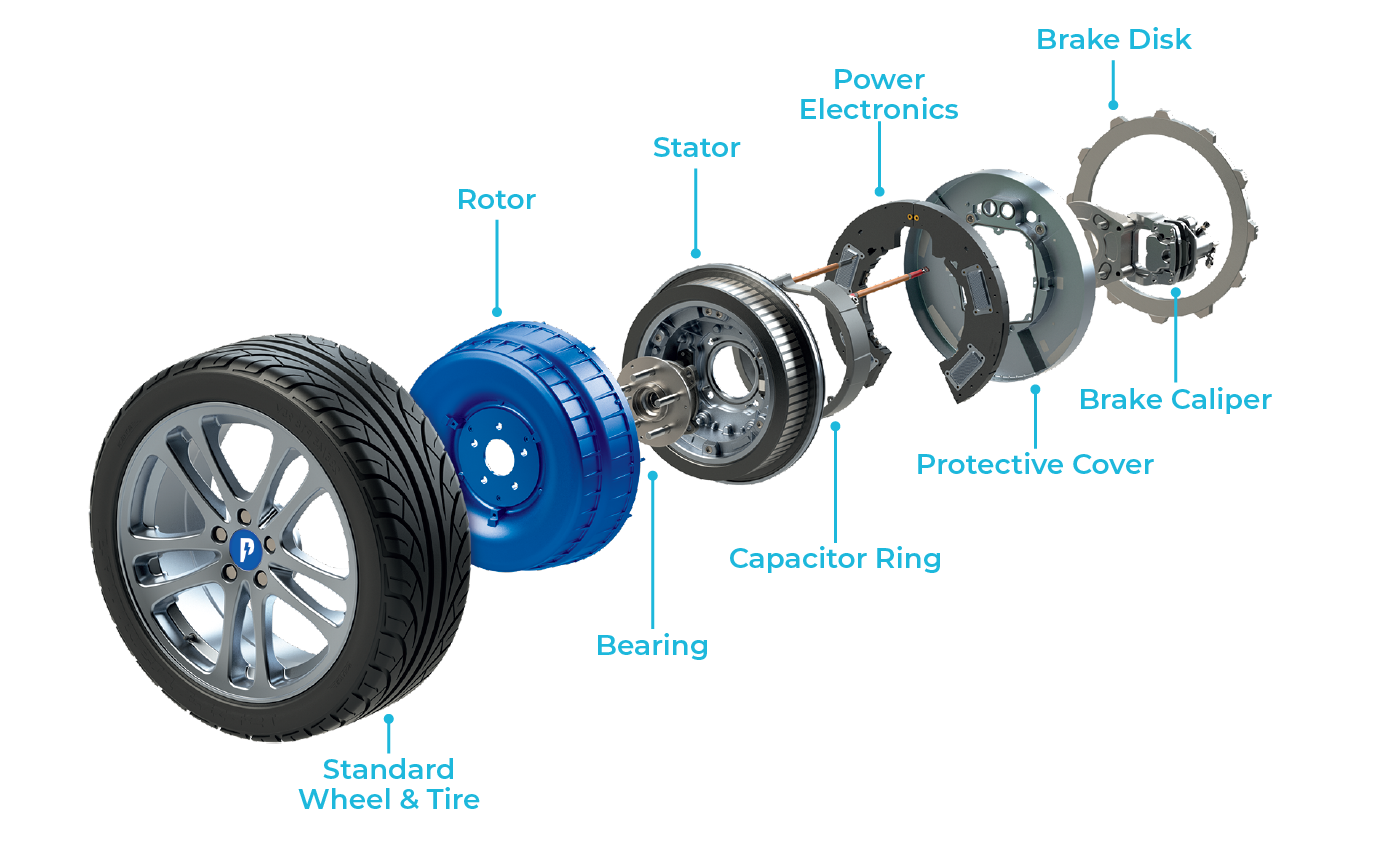

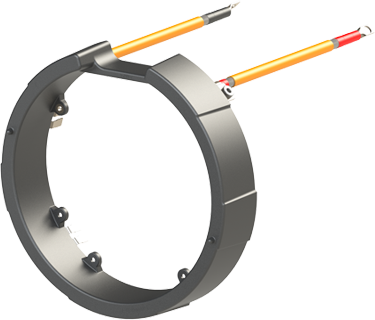

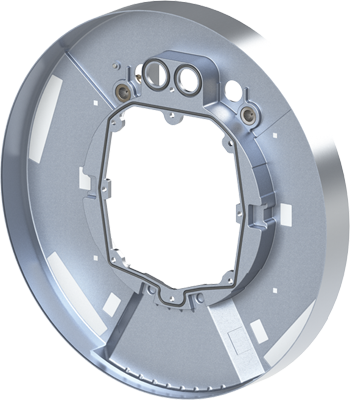

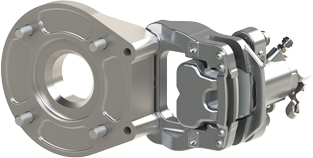

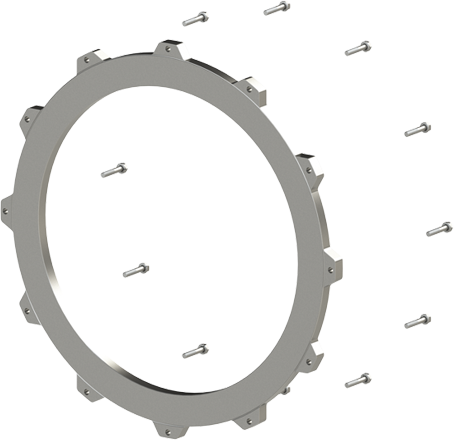

We offer direct drive in-wheel electric motors for passenger cars and light commercial vehicles based on our ProteanDrive technology. The motor, inverter and control are integrated in a single package alongside a compatible friction brake, offering high torque density and efficiency with excellent NVH characteristics. ProteanDrive is a scalable technology, enabling us to create products for a wide range of applications.

ProteanDrive provides a drivetrain solution without the need for packaging components on the vehicle body, unlocking new vehicle design freedom.

Models |

Pd18 |

Pd16 |

Peak Torque |

Peak TorqueMaximum rotational force delivered 1,500 Nm |

Peak TorqueMaximum rotational force delivered 800 Nm |

Peak Power |

Peak PowerMaximum power 103kW |

Peak PowerMaximum power 40 kW |

Max Speed |

225 km/h or 140 mph |

150 km/h or 93 mph |

Motor Weight |

39 kg |

28 kg |

Continuous Power |

Continuous PowerIndefinite power 54 kW |

Continuous PowerIndefinite power 26 kW |

Vehicle Weight |

Vehicles <5,200kg / 11,460 lb |

Vehicles <3,200 kg / 7,050 lb |

Total Wheel Power |

Comparable power to:Mercedes C 250 d BWM i3 2x motors 206 kW (276 hp) Comparable power to:Porsche 911 Carrera S Range Rover Sport 4x motors 412 kW (553 hp) |

Comparable power to:VW Polo SE 1.6 TDI Fiat 500 2x motors 80 kW (107 hp) Comparable power to:Audi A4 Ford Focus 1.5 EcoBoost 4x motors 160 kW (215 hp) |

Vehicle Types |

|

|

How it works

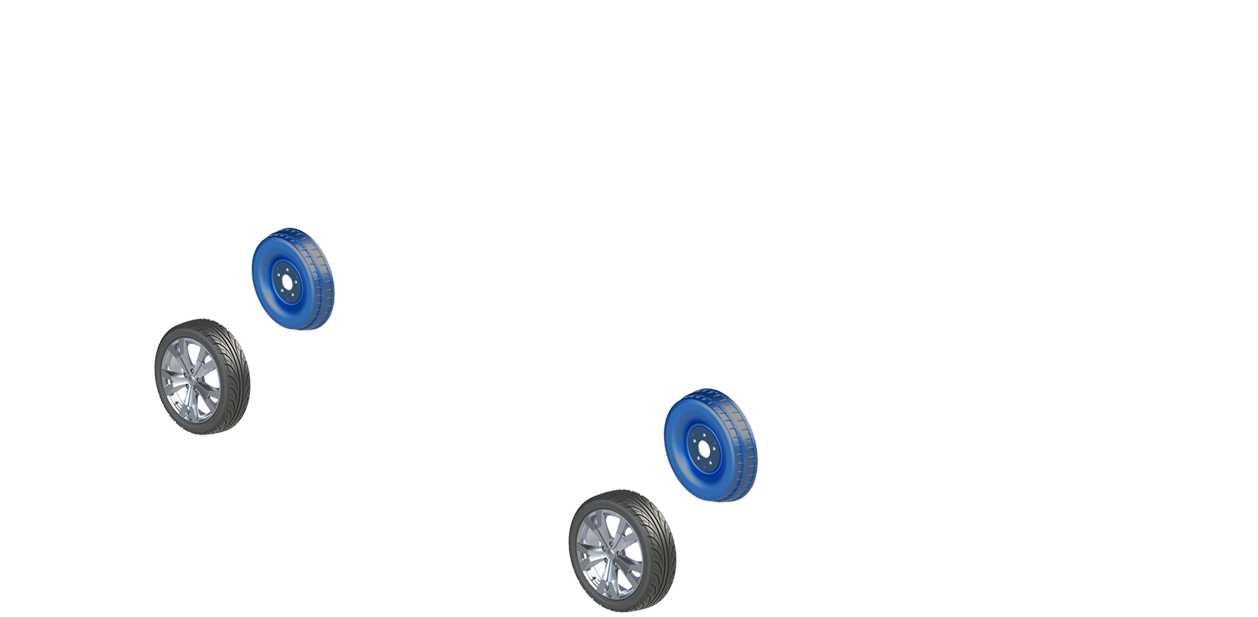

How it integrates

Pd18

In-wheel motor

Pd18

Wheel and tire

Pd16

In-wheel motorPd16

Wheel and tireProtean360+

Advanced electric-drive corner module designed for next-generation urban mobility pods.

Transport-as-a-Service urban mobility is gaining momentum, and with it the need for a new class of urban transport vehicles. Whether shared or private, for passengers or goods deliveries, human-driven or autonomous, these new vehicles will require new technologies to be fit for purpose. The Protean360+ corner module was borne from our team’s innovative thinking about how to meet the requirements for these next-generation urban vehicles.

- Limitless 360-degree-and-beyond steering provides exceptional vehicle manoeuvrability

- Pneumatic ride-height control enables ‘kneeling’ for stepless kerb-to-vehicle access

- Patent-pending quad-pivot lower wishbone design allows ultra-compact suspension setup

- Fully integrated in-wheel motor delivers power with maximum efficiency

- Module enables front, rear and side access into vehicles

- Single module design is common across all four corners of the vehicle

View the Protean360+ Fact Sheet

Accelerate the urban mobility revolution with Protean360+

From Theory To Reality

At our Tianjin manufacturing centre we have moved beyond development and testing to define and prove the process for mass production.

Solution Development

Our engineering capability covers the full development of an in-wheel motor solution for all vehicle applications.

Services we offer include:

- Mechanical Design

- Control System Supply and Calibration

- Brake Supply

- Integration Services

- Calibration

- Testing

- Complete Demo Vehicle Build

- Vehicle Simulation

- Dyno Facilities

Our whole development process strictly follows ISO26262 Functional Safety requirements. We ensure that our motors operate safely on a vehicle, and as such we will ensure that ProteanDrive integrates into the Functional Safety architecture of our customer’s vehicles.