News

Protean Electric acquired by EXEDY Corporation

Our innovative in-wheel motor technology generates power directly in a vehicle’s wheels.

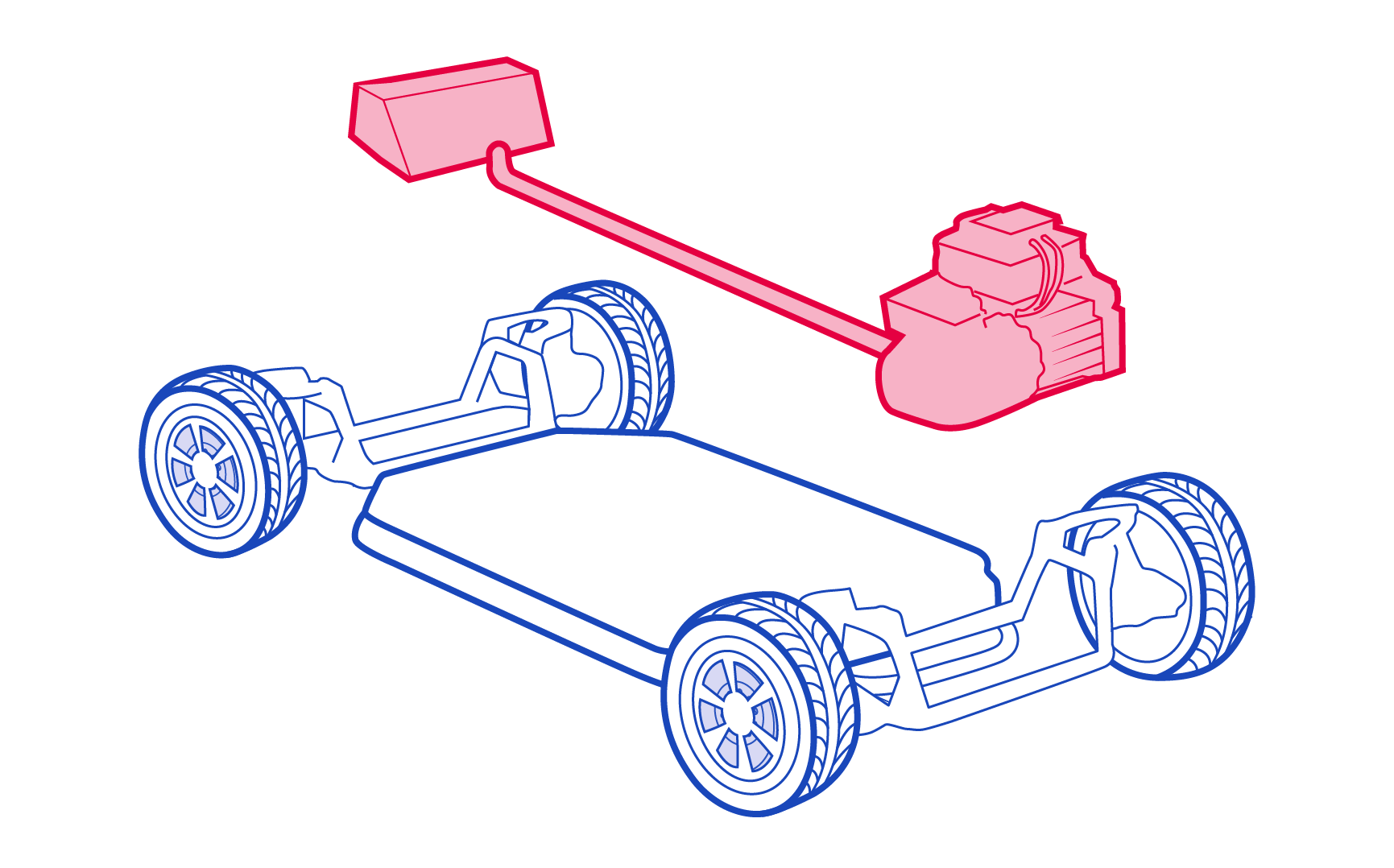

The electric vehicle revolution has grown out of conventional vehicle design. It made sense to start the shift to electric power with traditional single, central motor and drivetrain technologies. But electric power creates opportunities to innovate.

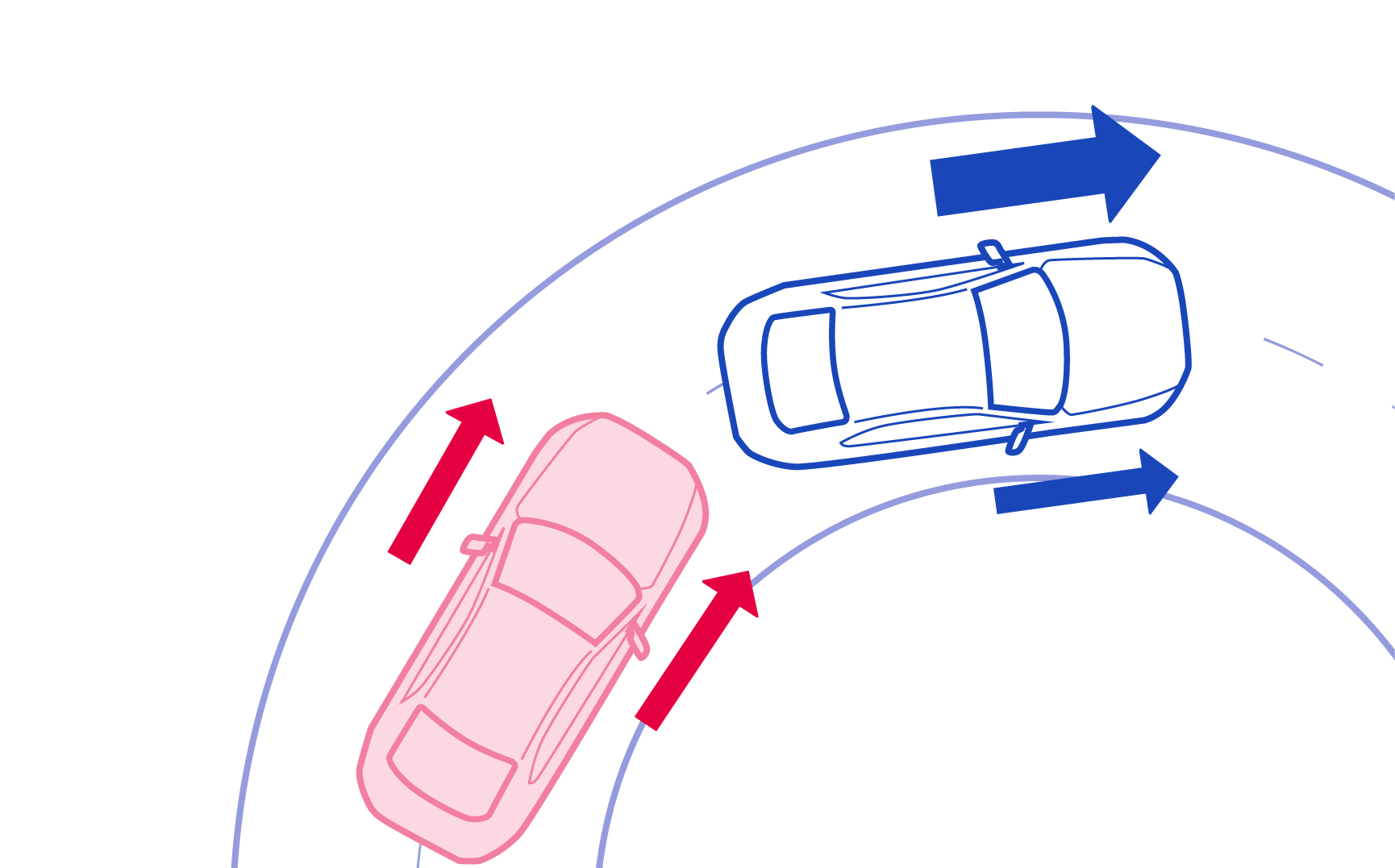

By moving power to the wheel, we have created a technological leap forward. In-wheel motors, also known as hub motors, give drivers improved torque response, enhanced handling, faster acceleration, less charging and greater range.

Our ProteanDrive in-wheel motors have integrated power electronics and digital control. Direct drive means no gears are required, and by partnering with leading brake system experts we have developed friction brakes that suit any type of vehicle.

In-wheel motors remove efficiency losses associated with gear, differential and CV joints situated around the vehicle. Total vehicle weight is also reduced.

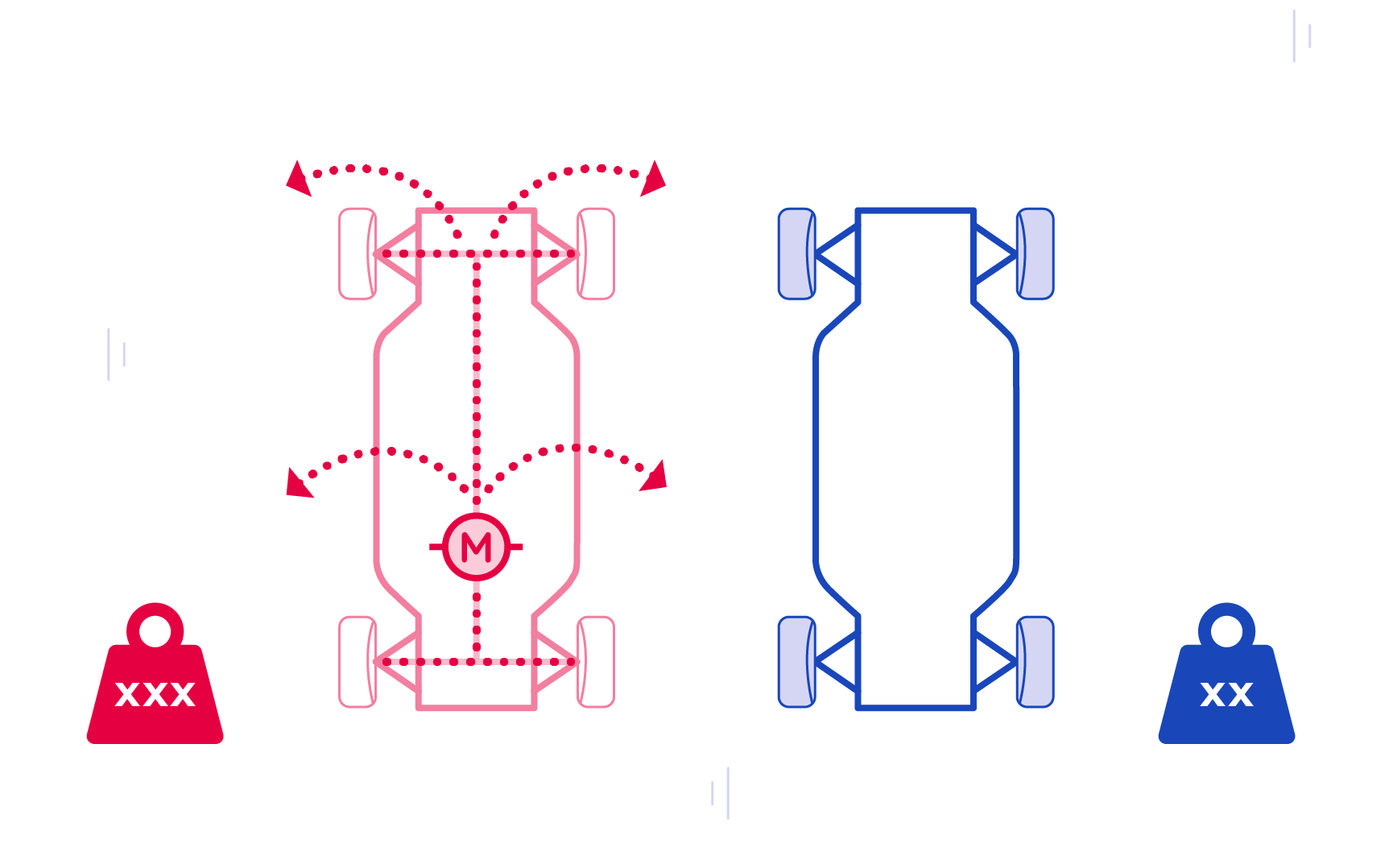

This means:

Individual wheel motors provide torque

distribution to different wheels (torque

vectoring)

This means:

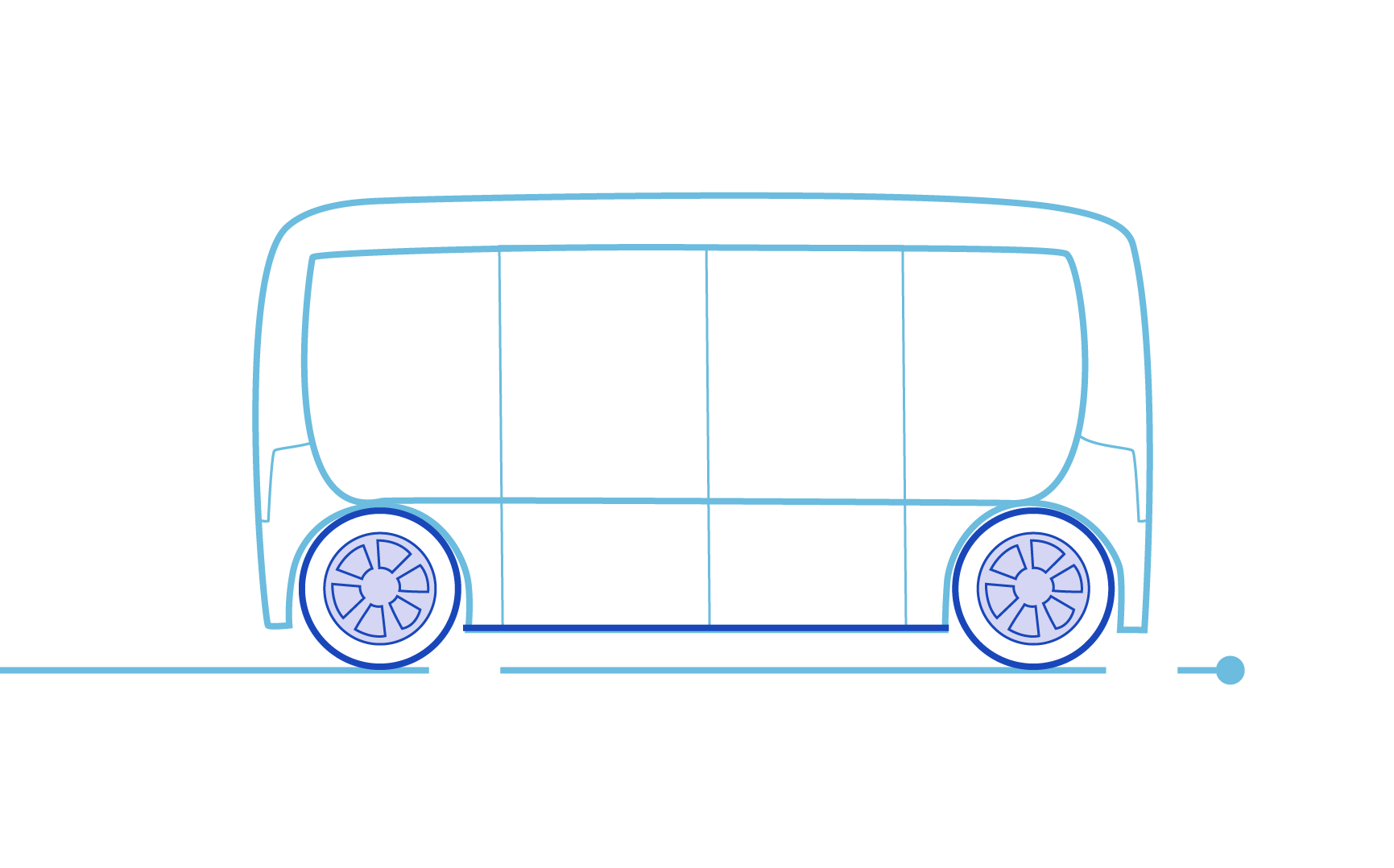

In-wheel motors revolutionize car design. No requirement for existing driveline components means vehicle design can unlock opportunities for new services and revenue

This means:

In-wheel motors with integrated inverters do not require a gear, differential, drive-shafts or external drive electronics.

This means: